Yes, Mini Cooper engines are BMW-made, embodying a blend of iconic British charm with unmatched German engineering. Manufactured in BMW's Hams Hall Plant in the UK and Plant Steyr in Austria, these engines are a result of strategic collaboration, bringing BMW's technological prowess and high-performance standards to the Mini lineup. With a range of 134 to 189 horsepower, Mini Cooper engines come in 1.5-liter three-cylinder and 2-liter four-cylinder variants, featuring advanced BMW technology like Valvetronic and Efficient Dynamics. Their reliability and performance have greatly benefited from BMW's engineering expertise, making them more robust and dynamic. Exploring further will reveal the intricacies and advantages of this partnership.

Engine Origins

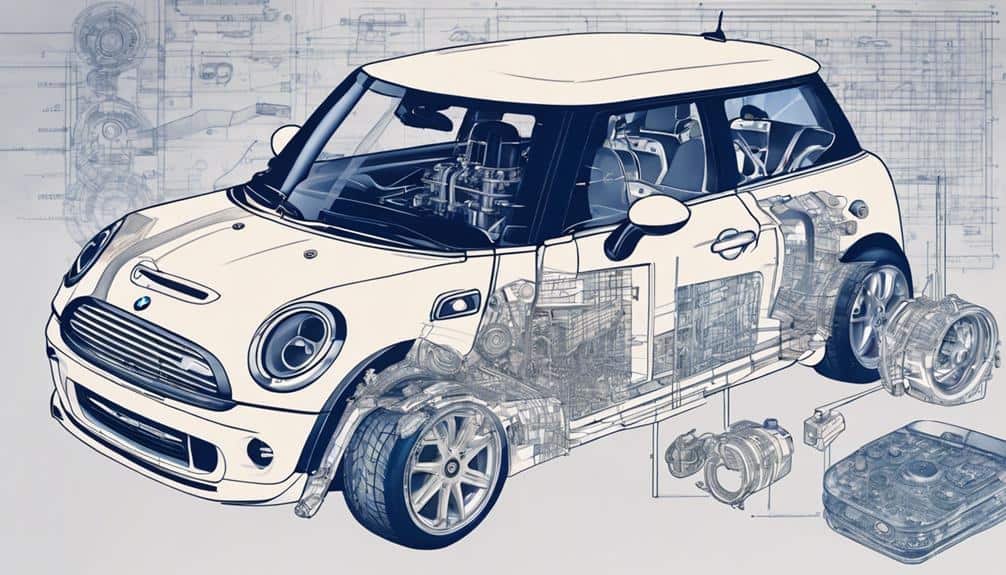

The engines powering Mini Coopers originate from BMW, reflecting a strategic partnership that leverages BMW's advanced engineering capabilities for Mini's lineup. This collaboration guarantees that Mini Coopers are equipped with engines that embody the pinnacle of automotive engineering, thanks to their BMW roots. The engines, manufactured by BMW, a venerable German brand, are a confirmation of the synergy between BMW's innovative prowess and Mini's iconic brand identity.

BMW's manufacturing plants, including the Hams Hall Plant in the UK for petrol engines and Plant Steyr in Austria for diesel engines, play a pivotal role in producing the engines for Mini Coopers. This geographical diversity in manufacturing underscores BMW's global footprint and its commitment to supplying Mini with engines that meet stringent quality and performance standards. The engine origins are hence a vital component of the Mini Cooper's identity, ensuring that every Mini model benefits from BMW's engineering excellence.

This direct sourcing of engines from BMW to Mini models maintains a consistent quality and performance standard across the Mini lineup. It's a clear indication that when you're driving a Mini Cooper, you're experiencing the engineering marvels of BMW, tailored to fit the unique character of a Mini.

BMW's Influence

Understanding BMW's ownership and its manufacturing intricacies sheds light on how deeply Mini Cooper engines are influenced by BMW's engineering philosophy and standards. As you explore the world of automotive engineering, it's crucial to acknowledge the symbiotic relationship between BMW and Mini Cooper engines. This connection isn't just about branding; it's about the infusion of high-grade technology, expertise, and manufacturing processes that BMW brings to the table.

BMW's influence on Mini Cooper engines extends beyond mere oversight. It's a complete integration of BMW's advanced technology and rigorous engineering standards into the core of Mini Cooper's performance. This ensures that each engine not only meets but often exceeds the expectations for reliability, efficiency, and power.

| Aspect | BMW Influence | Impact on Mini Cooper Engines |

|---|---|---|

| Design | Cutting-edge engineering | Enhanced performance |

| Production | Precision in manufacturing processes | Superior build quality |

| Technology | Advanced technological integration | Increased efficiency and power |

| Engineering Standards | High-quality control measures | Greater reliability |

| Performance | Benchmarking for excellence | Meets high-performance standards |

BMW's involvement guarantees that Mini Cooper engines are a product of sophisticated engineering and manufacturing processes, ensuring that they stand out regarding performance, reliability, and quality.

Engine Specifications

You'll find that Mini Cooper engines, crafted by BMW, offer a range of power outputs tailored to meet diverse driving demands.

The types of engines available in these vehicles vary, providing a spectrum of performance characteristics from fuel efficiency to high-speed capability.

Analyzing engine specifications reveals how BMW's engineering prowess enhances the Mini Cooper's performance and driving experience.

Power Output Range

Mini Cooper engines, crafted by BMW, offer a power output range from 134 to 189 horsepower, showcasing a diversity designed to meet varying performance needs. You'll find that the specific model and year of your Mini Cooper directly influence the power output, thanks to BMW's meticulous engineering.

| Model Year | Engine Type | Power Output (HP) |

|---|---|---|

| 2021 | 1.5-liter three-cylinder | 134 |

| Various | 2-liter four-cylinder | 189 |

| Specific Model Dependent | Varies | |

| VIN Number Specific | Varies | |

| BMW Manufactured | 134 to 189 |

This precision in power output guarantees that every Mini Cooper model delivers a performance that's both dynamic and tailored to the driver's expectations.

Engine Types Available

Exploring the engine types available in Mini Coopers reveals a range of specifications designed to optimize performance and efficiency. The engine lineup includes 1.5-liter three-cylinder and 2-liter four-cylinder petrol engines, each product of a joint venture between BMW and PSA Peugeot Citroen. This collaboration marries German and French automotive technologies, crafting engines that aren't purely BMW but are greatly influenced by BMW's engineering prowess.

These engines, integral to the BMW Mini lineup, incorporate advanced BMW technologies like Valvetronic and Efficient Dynamics. This blend enhances performance and efficiency, showcasing the successful merger of expertise from both companies in the development of Mini Cooper engines. Such a partnership ensures that each engine is a reflection of the combined innovation of BMW and PSA Peugeot Citroen.

Reliability Insights

When it comes to the reliability of Mini Cooper engines, it's important to note that their performance has greatly improved in recent years, largely due to BMW's manufacturing expertise. With BMW at the helm, Mini Cooper engines benefit from the German brand's renowned quality control processes and engineering prowess. This relationship ensures that each Mini Cooper engine, irrespective of the model or year, adheres to a high standard of reliability and performance.

The evolution of Mini Cooper engines over time reveals a significant uptick in reliability scores. Modern models, in particular, have outperformed their predecessors, showcasing fewer mechanical issues and a longer lifespan. This improvement is a direct result of BMW's commitment to excellence and innovation in engine manufacturing. The diverse range of engine types available in Mini Cooper models, while offering varying performance characteristics, all share the common thread of BMW's quality assurance.

Furthermore, the emphasis on regular maintenance can't be understated. Following a strict maintenance schedule significantly enhances the engine's reliability. By making sure that your Mini Cooper receives timely check-ups and care, you're investing in the longevity and consistent performance of a BMW-manufactured engine. This proactive approach to maintenance is essential for maximizing the reliability and efficiency of your Mini Cooper engine.

Cost of Replacement

When you're facing a Mini Cooper engine replacement, you'll find that the cost is greatly influenced by factors such as the model year and specific engine type. Understanding labor costs is important, as rates can vary widely between independent mechanics and authorized dealerships.

Additionally, the presence or absence of a warranty can greatly impact the overall expense, making it essential to evaluate your coverage before proceeding with any replacement work.

Replacement Price Factors

Several factors greatly influence the cost of replacing a Mini Cooper engine. Labor costs, parts availability, and your location all play a significant role.

Engine types are a crucial consideration, especially those manufactured at Plant Oxford or the high-performance variants in Mini Cooper S models. These models often feature the sophisticated Tritec engine, which can be more expensive to source and install due to its complexity and the engineering precision required.

The cost variance also hinges on the model year. Older Mini Coopers might see a steeper price due to the scarcity of parts, while newer models benefit from more readily available components.

Consulting a reputable mechanic or dealership is crucial for an accurate estimate. They can assess the specific requirements based on the engine type and model intricacies.

Labor Costs Explained

Understanding the labor costs involved in replacing a Mini Cooper engine requires a closer look at factors such as the mechanic's location, their hourly rates, and the specific model of your vehicle. The variability in labor costs can be attributed to the engine's complexity, which is influenced by its design at the BMW engine plant. Different models may require different amounts of labor due to the intricacies of their engines, which have evolved over generations of Mini Coopers.

| Location | Independent Shop Cost | Dealership Cost |

|---|---|---|

| Urban | $1,200 | $1,500 |

| Suburban | $1,000 | $1,300 |

| Rural | $800 | $1,100 |

| Average | $1,000 | $1,300 |

| Model Variation | +/- 10% | +/- 15% |

Proper maintenance and timely repairs at authorized centers can help in minimizing the overall labor costs, ensuring your vehicle remains in top condition without unexpected hikes in service charges.

Warranty Impact on Price

Exploring the relationship between BMW's warranty policies and the cost of replacing a Mini Cooper engine reveals how ownership can influence financial implications for vehicle owners.

BMW's stewardship over Mini Cooper engines ensures a certain level of quality and performance. However, it's the warranty coverage that greatly impacts the cost dynamics of engine replacement.

If your Mini Cooper is still under warranty, the financial burden of replacing the engine can be drastically reduced. This is because warranty coverage, contingent on the model and year of your Mini Cooper, may cover most, if not all, of the replacement costs.

It's important to understand how warranty specifics can affect the price you'll pay. Managing BMW ownership with a keen awareness of warranty implications is essential for controlling costs effectively.

Common Engine Issues

Mini Cooper engines, produced by BMW, aren't immune to issues, with common problems including carbon buildup and oil blockages in models from 2007 to 2014. This specific range of issues highlights an essential vulnerability in the engine design, impacting overall engine performance and reliability. Moreover, older Mini Cooper models, especially those manufactured between 2006 and 2012, have been marked by lower reliability scores, largely attributed to various engine-related complications. These models are particularly susceptible to a range of malfunctions that can compromise vehicle performance and longevity.

Understanding the intricacies of these common engine issues requires a technical appreciation of how carbon accumulation and oil blockages can severely hamper engine efficiency. Carbon buildup, for instance, can lead to reduced air flow and engine overheating, while oil blockages can starve the engine of necessary lubrication, causing premature wear. The engine light indicator serves as an important diagnostic tool, flagging up minor to severe problems within the On-Board Diagnostics (OBD) system. Regular maintenance, although not the focus here, emerges as a crucial strategy in mitigating these issues, emphasizing the need for continuous monitoring and intervention to sustain engine health and function.

Maintenance Tips

To mitigate common engine issues previously discussed, it's essential you adhere to thorough maintenance practices for your Mini Cooper's engine. Regular oil changes and filter replacements are key to maintaining the health of your Mini Cooper's engine, especially for those equipped with the Prince engine, known for its deployment in Mini Cooper S models. This component, produced at the Hams Hall Plant, demands high-quality lubrication to sustain its performance and longevity.

Monitoring coolant levels and ensuring the cooling system functions correctly are critical in preventing overheating, a significant risk for compact engines like those in Mini Coopers. Adhering to the manufacturer's recommended service schedule for spark plug replacement can markedly improve your vehicle's engine performance, ensuring that each ignition is as efficient as possible.

Moreover, inspecting and replacing worn or damaged belts and hoses is crucial to prevent engine component failures. These components are essential for maintaining the engine's timing and cooling processes, directly impacting the engine's reliability and efficiency.

Lastly, using high-quality fuel and manufacturer-recommended additives is important for keeping your Mini Cooper engine running smoothly. This practice helps in minimizing deposit buildup and maintaining optimal engine function.

Conclusion

Essentially, the heart of your Mini Cooper doesn't just beat—it roars with BMW's engineering prowess. With BMW's touch, your Mini isn't just a car; it's a masterpiece of precision, blending high-end performance with reliability.

However, when it comes to replacement, the costs can sky-rocket, potentially burning a hole in your pocket. Common engine issues can be mitigated with diligent maintenance, ensuring your Mini runs smoothly.

Remember, keeping your Mini in peak condition is akin to safeguarding a piece of automotive royalty.