To change a ball joint on your Mini Cooper, start by safely jacking up your car and securing it on jack stands. You'll need to disconnect the sway bar link and tie rod end for better access. After removing the wheel and braking components, proceed to extract the old ball joint by removing its fasteners and detaching the nut with an open-end wrench. Install the new ball joint with precise alignment, securing it with a ball joint press tool and tightening the nut to the manufacturer's torque specifications. Reassembling requires caution, making sure every component is adjusted and greased properly. Following these steps will guarantee a successful replacement, enhancing smoother rides and improved handling.

Preparing Your Mini Cooper

Before tackling the ball joint replacement, you'll first need to safely jack up your Mini Cooper and secure it on jack stands to create a stable working environment. This initial step is vital to guarantee your safety and provide ample space for maneuvering underneath the vehicle. Once elevated, you'll gain better visibility and access to the suspension components, specifically the control arms and the ball joint you're about to work on.

Next, you'll need to disconnect the sway bar link and the tie rod end. This step is essential for creating enough clearance to work on the ball joint without obstruction. Use a torque wrench to loosen and remove the bolts securely. Pay attention to the torque specifications, as this precision tool ensures you apply the correct amount of force, preventing damage to the parts or your Mini Cooper.

Before you proceed to unbolt the control arm to access the ball joint, it's imperative to inspect the surrounding components for any signs of wear or damage. Identifying and addressing these issues beforehand can save you time and avoid potential complications during the ball joint replacement process. This preparatory phase sets the foundation for a successful repair, emphasizing safety, precision, and thoroughness.

Removing the Wheel and Brake Components

To begin removing the wheel and brake components, first use a lug wrench or impact gun to loosen and remove the wheel's lug nuts. This step is important for gaining access to the ball joint and control arm assembly. Once the wheel is off, you'll see the brake caliper mounted over the rotor. Using a socket wrench or an impact gun, carefully undo the caliper bolts. It's essential to handle this part gently to avoid damaging the brake line.

Next, secure the caliper out of the way by hanging it with a wire or zip tie. This precaution prevents any strain on the brake line while you're working on the inner ball joint and control components. With the caliper secured, you can now remove the brake rotor. Simply pull it off the hub to expose the area around the ball joint.

During this process, take the opportunity to inspect the brake components for any wear or damage. Identifying issues early can save you time and make sure your Mini Cooper's braking system remains in top condition as you proceed to work on the ball joint and control arm.

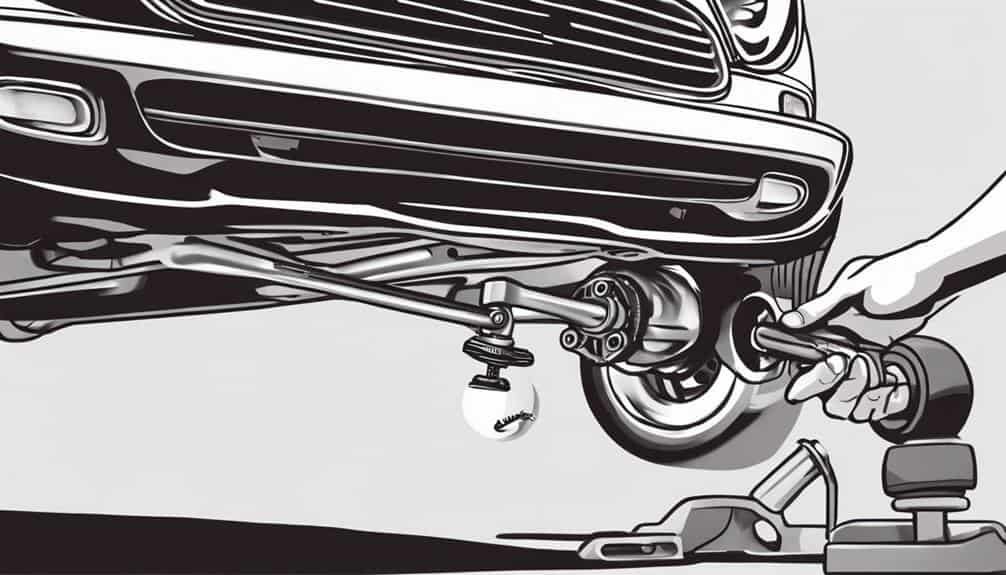

Extracting the Old Ball Joint

Having removed the wheel and brake components, you'll next focus on extracting the old ball joint from your Mini Cooper. This process begins with the removal of the front ball joint's 12mm fasteners, which secure it to the control arm. Carefully unscrew these fasteners to detach the ball joint from its position.

Next, employ a lever to pry the front ball joint away from the lower control arm. This step requires patience and precision to avoid damaging surrounding components. Once loosened, the ball joint's connection to the lower control arm will be notably weakened, facilitating further steps.

The removal process continues with the detachment of the 18mm ball joint nut located at the steering knuckle. Use an open-end wrench to loosen and remove this nut, thereby releasing the ball joint from its anchored position.

Installing the New Ball Joint

Once you've successfully removed the old ball joint, it's time to install the new one using a ball joint press tool for secure placement. This step is important in making sure that your Mini Cooper's suspension remains strong and reliable.

Here's a concise guide to help you through the installation process:

- Align the New Ball Joint:

- Carefully position the new ball joint in the control arm or steering knuckle. Make sure it's aligned properly to avoid any issues with vehicle handling or tire wear. Proper alignment is key to the best performance of your ball joints.

- Use the Ball Joint Press Tool:

- With the ball joint positioned correctly, use the ball joint press tool to press the ball joint into place. Make sure the tool is properly set up to avoid damaging the new ball joint or the surrounding components.

- Secure and Grease the Ball Joint:

- Tighten the ball joint nut to the manufacturer's specified torque setting to ensure it's firmly fastened. Applying a small amount of grease facilitates smooth movement and helps in prolonging the life of the ball joint.

Double-check the installation to confirm the ball joint is securely in place and properly aligned before moving on to reassembly. Proper installation and alignment are essential to achieving a smooth ride and maintaining the longevity of your vehicle's suspension system.

Reassembly and Final Checks

After installing the new ball joint, it's time to focus on reassembly and conducting final checks to make sure everything functions as intended. Begin the reassembly process by using new kits, making sure all components are fresh and free from wear. It's important to adjust preload with shims to achieve the proper functioning of the ball joint. This adjustment ensures the ball joint moves smoothly without being too tight or too loose, which is vital for both peak performance and safety.

Next, tighten the dome nut to the specified torque as recommended by the manufacturer. Applying the correct torque is crucial for maintaining the integrity of the ball joint connection. Following this, apply grease, specifically moly grease, to the ball joint. This type of grease is recommended for its properties that ensure smooth movement and longevity, while also offering rust prevention.

Your final inspection should include testing the ball joint to ensure it moves freely without play or binding. Double-check all your work, making sure every component is properly installed and all fasteners are torqued to the manufacturer's specifications. This final inspection is important to ensure that your Mini Cooper is safe to drive, maintaining peak performance and preventing premature wear.

Conclusion

Once you've replaced the ball joint on your Mini Cooper, it's important to make sure everything is reassembled correctly. Tighten all nuts and bolts to the manufacturer's specifications to maintain safety and performance.

Before you hit the road, perform a thorough check to verify that all components are securely in place. This final step confirms the integrity of your work, safeguarding your vehicle's functionality.

Remember, precision in these tasks is key to a smooth, safe drive.