When working on a Mini Cooper, keep in mind that its firing order is 1-3-4-2 for 4-cylinder engines. This sequence guarantees smooth engine operation and maintenance. Be sure to align the distributor rotation counter-clockwise for the correct firing order and peak engine performance. Connecting the spark plug wires in the sequence of 1-3-4-2 is crucial to prevent misfiring and maintain efficiency in engine operation. Paying attention to these details will keep your Mini Cooper running smoothly and efficiently.

Understanding Mini Cooper Firing Order

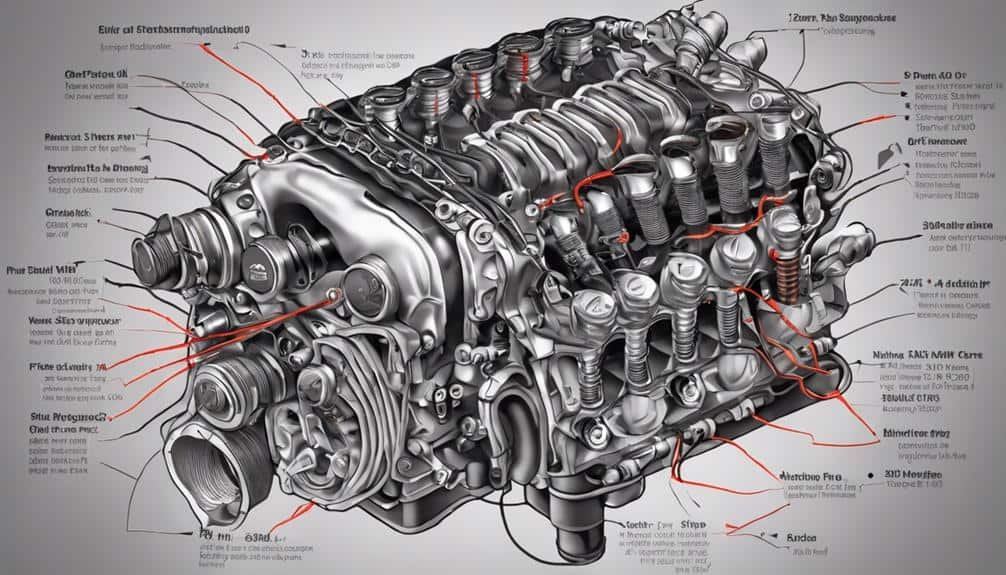

To understand the Mini Cooper firing order, note that it follows a specific sequence of 1-3-4-2 for its 4-cylinder engines. In Mini Coopers, the cylinder numbers are arranged starting from the timing chain side as 1-2-3-4. The N14 and N18 engines found in Mini Coopers are flat plane crank engines. It's important to recognize that the physical location of the 1/4 and 2/3 pistons is the same, but they fire at a 180-degree offset from each other.

Confirming the firing order can be done by examining the camshaft lobes in Mini Cooper engines. The precise timing and sequence of the firing order are critical for the engine to operate smoothly and efficiently. Understanding this firing order layout is essential for proper maintenance, troubleshooting, and tuning of Mini Cooper engines. By following the 1-3-4-2 firing order, you make certain that the combustion process occurs in the correct sequence, allowing your Mini Cooper to perform at its best.

Distributor Rotation Importance

Examining the distributor rotation in your Mini Cooper is essential for ensuring the accurate delivery of spark to each cylinder in the engine. Understanding the importance of distributor rotation can lead to peak engine performance. Here are key points to take into account:

- Counter-clockwise Rotation: Many engines, including the Mini Cooper, typically rotate the distributor in a counter-clockwise direction. This rotation direction is vital for the correct firing order sequence.

- Influence of Distributor Cap Style: The design of the distributor cap, such as side-load, plays a significant role in determining the arrangement of the spark plug wires. Proper alignment based on the distributor cap style ensures the spark reaches the right cylinder at the right time.

- Alignment with Spark Plug Position: Aligning the distributor rotor with the #1 spark plug position is essential for maintaining precise ignition timing. This alignment guarantees that each cylinder receives the spark in the correct sequence for efficient engine operation.

Plug Wire Connection Sequence

When connecting plug wires in a Mini Cooper, remember the sequence is 1-3-4-2, vital for proper engine function.

Start from the front cylinder and work counterclockwise to guarantee accurate connection.

Following this order is essential to prevent misfiring and maintain peak engine performance.

Firing Order Basics

Understanding the firing order sequence, 1-3-4-2, is crucial for guaranteeing top engine performance in a Mini Cooper. Here are some key points to contemplate:

- Cylinder Firing Order: The firing order indicates the specific order in which each cylinder in the engine receives spark to ignite the air-fuel mixture.

- Engine Efficiency: Following the correct firing order ensures that each cylinder fires at the right time, optimizing engine efficiency and power output.

- Misfire Prevention: Adhering to the correct firing order prevents misfires, which can cause rough idling, decreased fuel efficiency, and potential damage to the engine components.

Cylinder Numbering System

To correctly identify the cylinder numbering system for the Mini Cooper's plug wire connection sequence, refer to the engine's timing chain side, starting with cylinders numbered 1-2-3-4. Cylinder number one is closest to the master cylinder, followed by cylinders two, three, and four in sequence.

The correct arrangement is vital for ensuring the firing order (1-3-4-2) aligns with the engine's design. In Mini Cooper engines, the camshaft lobes are a visual indicator of the firing order, making it easier to verify proper cylinder identification.

Understanding the cylinder numbers and their corresponding positions will help you connect the plug wires accurately, ensuring excellent engine performance and efficiency. Mastering the cylinder numbering system is essential for maintaining the Mini Cooper's engine functionality.

Correct Plug Installation

Starting with the front cylinder, connect the plug wires counterclockwise in the sequence 1-3-4-2 for proper installation on a Mini Cooper.

Make sure that the distributor rotor aligns with the #1 spark plug location by following these steps:

- Align the distributor rotor with the #1 spark plug position.

- Connect the plug wires in the order of 1-3-4-2 to the distributor.

- Utilize the Top Dead Center (TDC) of the #1 piston to guide the placement of the plug wires accurately.

Spark Plug Location Alignment

When addressing spark plug location alignment in your Mini Cooper, it's essential to understand the specific spark plug types recommended for your engine.

Proper installation tips, such as torque specifications and gap settings, play a critical role in achieving peak performance.

Ensuring the correct alignment of spark plugs will maintain ignition timing accuracy and support efficient engine operation.

Spark Plug Types

For best engine performance in your Mini Cooper, selecting the appropriate spark plug types is essential. When considering spark plug types, keep in mind the following:

- Copper Spark Plugs: These are the most affordable option and have good conductivity but may wear out faster.

- Platinum Spark Plugs: Offering a longer lifespan and better performance than copper plugs, they're a popular choice for many Mini Cooper owners.

- Iridium Spark Plugs: Known for their durability and longevity, iridium plugs are often the top choice for high-performance engines, ensuring consistent ignition and combustion efficiency.

Remember that the right spark plug type, along with correct placement in the spark plug location, is critical for maintaining your Mini Cooper's engine in top condition.

Installation Tips

To ensure accurate alignment of spark plug locations in your Mini Cooper, start with the front cylinder and proceed in a counterclockwise direction, ensuring the distributor rotor aligns with the #1 spark plug position for precise ignition timing.

Essential spark plug installation is vital for the firing order and overall engine performance. Connect the plug wires in the sequence 1-3-4-2 to match the firing order of the Mini Cooper engine. Utilize the top dead center (TDC) position of the #1 piston to accurately place the plug wires.

Refer to the table below for a clearer understanding of the spark plug installation and firing order in your Mini Cooper.

Troubleshooting Engine Start Issues

Check the distributor dog-drive position to guarantee proper engagement when troubleshooting engine start issues on a Mini Cooper. Make sure the rotor aligns with the #1 spark plug for correct ignition timing. Using the correct wire length for plug connections is important to prevent misfires.

To troubleshoot engine start problems effectively, follow these steps:

- Confirm Piston at TDC: Before setting up wires, ensure that the piston is at Top Dead Center (TDC). This ensures proper timing alignment.

- Check Firing Order Sequence: Follow the firing order sequence (1-3-4-2) meticulously. Any deviation can lead to engine start issues and misfires.

- Inspect Spark Plug Wires: Verify that the spark plug wires are connected securely and are of the appropriate length. Incorrect wire lengths can cause weak sparks or misfires, affecting the engine start.

Common Mistakes to Avoid

When ensuring proper engine performance on a Mini Cooper, be cautious of common mistakes to avoid in the firing order sequence and spark plug wire connections. Misfiring issues can arise if the distributor dog-drive position is incorrect, leading to engine inefficiency.

Additionally, rotor misalignment with the #1 spark plug can result in troublesome engine starting problems. Using spark plug wires that are too short for proper connections may cause poor engine performance, emphasizing the need for precise wire lengths.

Setting the piston at Top Dead Center (TDC) is vital to executing the correct firing order; failure to do so can lead to misfiring problems. It's essential to adhere to the specific 1-3-4-2 firing order sequence to prevent cylinder misfires and maximize engine function.

Collaborative Troubleshooting Solutions

For effective collaborative troubleshooting solutions, closely examine the distributor rotation and align the distributor rotor accurately with the #1 spark plug location in your Mini Cooper's engine. Follow these steps to guarantee proper troubleshooting:

- Check Firing Order: Verify that the firing order on your Mini Cooper is 1-3-4-2 for 4-cylinder engines. Incorrect firing order can lead to engine misfires and poor performance.

- Inspect Distributor Rotation: Remember that the distributor rotation in Mini Cooper engines is counter-clockwise. Make sure the distributor rotates in the correct direction to deliver spark at the right time to each cylinder.

- Align Distributor Rotor: Align the distributor rotor with the #1 spark plug location. This alignment is essential for connecting the plug wires in the correct order and maintaining proper engine timing.

Conclusion

Just as each note in a beautiful symphony plays an essential role in creating harmony, the firing order in a Mini Cooper engine is vital for smooth operation.

By understanding the distributor rotation, plug wire connection sequence, and spark plug location alignment, you can troubleshoot any engine start issues effectively.

Avoid common mistakes and work collaboratively to find solutions, ensuring your Mini Cooper runs like a well-tuned orchestra.